Equipment Check-out: Difference between revisions

m (Benoit moved page Order Fulfillment to Equipment Check-out) |

No edit summary |

||

| (10 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[Category: Rental Operations]][[Category: CurrentRMS]] | [[Category: Rental Operations]][[Category: CurrentRMS]] | ||

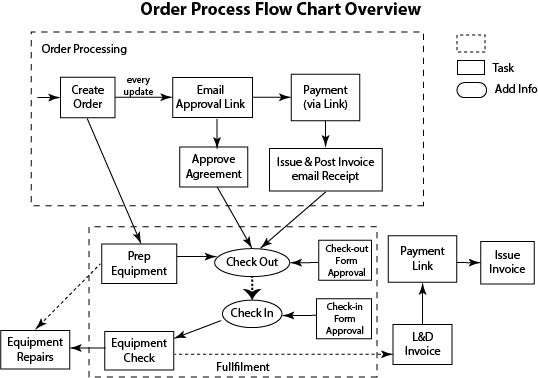

[[File:Order Processing Details.jpg|frame|center]] | |||

= Order Prep = | |||

Orders should be prepared 24 hours before pick-up to allow time to deal with issues that might arise. Only a single order should be worked on at a time, to minimize confusion and insure nothing is missed. | |||

1. Move Items to staging area | 1. Move Items to staging area | ||

| Line 11: | Line 10: | ||

If multiple small grip items are part of an order, it’s OK to put them in a milk crate, but ADD the milk crate(s) to the pick-up sheet! | If multiple small grip items are part of an order, it’s OK to put them in a milk crate, but ADD the milk crate(s) to the pick-up sheet! | ||

2. | 2. Prepare & Scan gear with Asset Tags | ||

* | * Make sure you are in the Detail View, Allocate Tab, "mark as prepared" slider is YES. | ||

* | * Make sure you are in the asset text box and scan the items with the scanner. | ||

* | ** A good scan should have a bloop sound with a green box | ||

* | ** A bad scan will have a glass shattering sound and a red box. | ||

* | ** If you get a bad scan, you should investigate why - Usually a Wrong item (Spring Loaded C-Stand instead of Non-Spring Loaded?) | ||

* Inspect the equipment as you scan it. | |||

3. Prepare & Account for Bulk Items | |||

* Switch to the function Tab, for each bulk items select the checkbox for those items. You can then use the Action > Prepare button to mark it prepared. | |||

4. Check for Group Booking entries. There should not be any. It denotes an issue. | |||

* | * Group Booking is a serialized asset that was not scanned. | ||

* Fix the problem: Is it a missing asset tag? Is it an unknown asset tag number? Let's solve it. | |||

* For equipment kits (dana dolly, teradek, Bartech, generators, etc…) it is essential that all accessories in the package should be accounted for. | |||

* | * Any accessory missing '''Post on slack's #current-rental''' so replacement can be ordered or the item located. | ||

* | * Any accessory damaged should be swapped out (if possible) and moved to the repair station. make a note on sheet and Post on slack's #current-rental. | ||

* | |||

= Client Pick-Up = | |||

When the client arrives to pick-up their equipment, | When the client arrives to pick-up their equipment: | ||

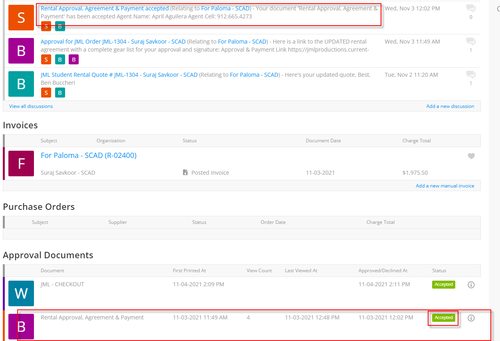

* Verify the has Accepted the Agreement | |||

** Under "Approval Documents", A document with "Agreement" in the title should be presend and marked "Accepted". | |||

** Sometimes it does not show up there. Look at the discussions and see if a document Accepted is present. | |||

[[file: Order_Accepted.png | border| 500px| center]] | |||

** "Rental Approval, Agreement & Payment accepted" either in the discussion section or approval Documents section. | |||

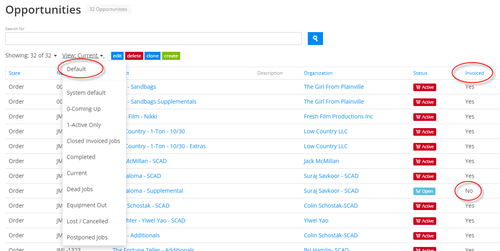

* '''Verify that the order has been paid for or will be paid for prior to departure.''' | |||

** In the "default" view, there is an invoiced column. | |||

** "Invoiced" being set to Yes means the order has been paid (see workflow... invoice is issued once payment is received). | |||

** When in doubt, call Sales agent to verify payment has been received. | |||

[[file: Is_Paid.png | border|500px | center]] | |||

* Client is free to test the equipment at the shop to insure it is in working order. | |||

* Once satisfied with the entire order, they perform an electronic signature on the checkout form. | |||

** On the shop tablet, find the order in Current RMS. | |||

** go to JML - CHECKOUT (under Print section on right hand side) | |||

** Select Approval URL | |||

** Click the Link | |||

** Click Approve | |||

** And tablet to client to fill name and sign pick-up form. | |||

'''Once client leaves with equipment, go to the order's Detail View, Function Tab, Select everything and use the Action > Book Out to mark everything as booked out.''' | |||

== Adding to order on the fly == | |||

Sometimes, additional equipment needs to be added to the order at pick-up. | Sometimes, additional equipment needs to be added to the order at pick-up. | ||

If the invoice has not been paid: | If the invoice has not been paid: | ||

* Agent should update the Order in CurrentRMS | * Agent should update the Order in CurrentRMS | ||

* | * Client needs to approve the updated order via link | ||

* | * Pay order via the updated link | ||

* | * Sales agent then issues, post and emails invoice | ||

* Make sure to use a new checkout form with the updated order. | |||

If the invoice has already been paid: | If the invoice has already been paid: | ||

* Agent should create a new order in CurrentRMS for the additional equipment | * Agent should create a new order in CurrentRMS for the additional equipment and add an "- ADDITIONAL" to the order name. | ||

* Client needs to approve the updated order via link | |||

* Pay order via the updated link | |||

* Sales agent then issues, post and emails invoice | |||

* | * Client fills out the 2nd checkout form too. | ||

* | |||

----- | |||

Updated: 11-01-2021 | |||

Latest revision as of 12:43, 10 January 2022

Order Prep

Orders should be prepared 24 hours before pick-up to allow time to deal with issues that might arise. Only a single order should be worked on at a time, to minimize confusion and insure nothing is missed.

1. Move Items to staging area

If multiple small grip items are part of an order, it’s OK to put them in a milk crate, but ADD the milk crate(s) to the pick-up sheet!

2. Prepare & Scan gear with Asset Tags

- Make sure you are in the Detail View, Allocate Tab, "mark as prepared" slider is YES.

- Make sure you are in the asset text box and scan the items with the scanner.

- A good scan should have a bloop sound with a green box

- A bad scan will have a glass shattering sound and a red box.

- If you get a bad scan, you should investigate why - Usually a Wrong item (Spring Loaded C-Stand instead of Non-Spring Loaded?)

- Inspect the equipment as you scan it.

3. Prepare & Account for Bulk Items

- Switch to the function Tab, for each bulk items select the checkbox for those items. You can then use the Action > Prepare button to mark it prepared.

4. Check for Group Booking entries. There should not be any. It denotes an issue.

- Group Booking is a serialized asset that was not scanned.

- Fix the problem: Is it a missing asset tag? Is it an unknown asset tag number? Let's solve it.

- For equipment kits (dana dolly, teradek, Bartech, generators, etc…) it is essential that all accessories in the package should be accounted for.

- Any accessory missing Post on slack's #current-rental so replacement can be ordered or the item located.

- Any accessory damaged should be swapped out (if possible) and moved to the repair station. make a note on sheet and Post on slack's #current-rental.

Client Pick-Up

When the client arrives to pick-up their equipment:

- Verify the has Accepted the Agreement

- Under "Approval Documents", A document with "Agreement" in the title should be presend and marked "Accepted".

- Sometimes it does not show up there. Look at the discussions and see if a document Accepted is present.

- "Rental Approval, Agreement & Payment accepted" either in the discussion section or approval Documents section.

- Verify that the order has been paid for or will be paid for prior to departure.

- In the "default" view, there is an invoiced column.

- "Invoiced" being set to Yes means the order has been paid (see workflow... invoice is issued once payment is received).

- When in doubt, call Sales agent to verify payment has been received.

- Client is free to test the equipment at the shop to insure it is in working order.

- Once satisfied with the entire order, they perform an electronic signature on the checkout form.

- On the shop tablet, find the order in Current RMS.

- go to JML - CHECKOUT (under Print section on right hand side)

- Select Approval URL

- Click the Link

- Click Approve

- And tablet to client to fill name and sign pick-up form.

Once client leaves with equipment, go to the order's Detail View, Function Tab, Select everything and use the Action > Book Out to mark everything as booked out.

Adding to order on the fly

Sometimes, additional equipment needs to be added to the order at pick-up.

If the invoice has not been paid:

- Agent should update the Order in CurrentRMS

- Client needs to approve the updated order via link

- Pay order via the updated link

- Sales agent then issues, post and emails invoice

- Make sure to use a new checkout form with the updated order.

If the invoice has already been paid:

- Agent should create a new order in CurrentRMS for the additional equipment and add an "- ADDITIONAL" to the order name.

- Client needs to approve the updated order via link

- Pay order via the updated link

- Sales agent then issues, post and emails invoice

- Client fills out the 2nd checkout form too.

Updated: 11-01-2021