Checkin An Item

1. Go to the Opportunity's Detail View and select Check-in tab

2. As you inspect the asset, scan the serialized barcodes. Asset will be checked-in.

3. If the item is dirty or damaged, it needs to be put in the quarantine.

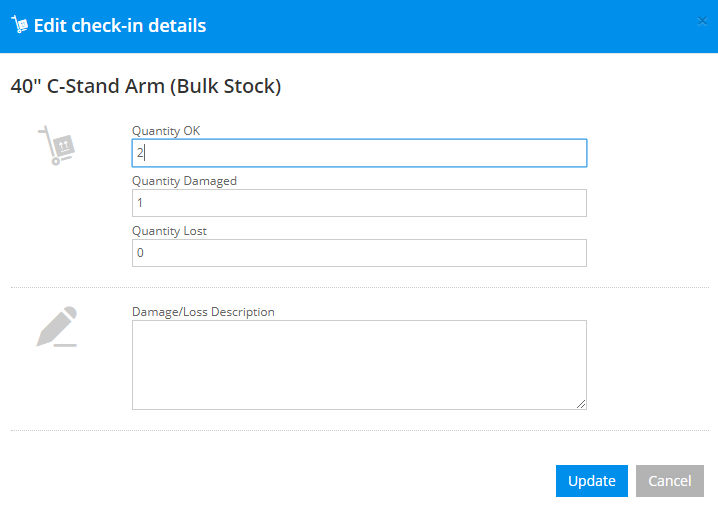

a) For bulk items, use the checkin menu and fill out the bulk check-in details. Do the same with Non-stock Booking line items.

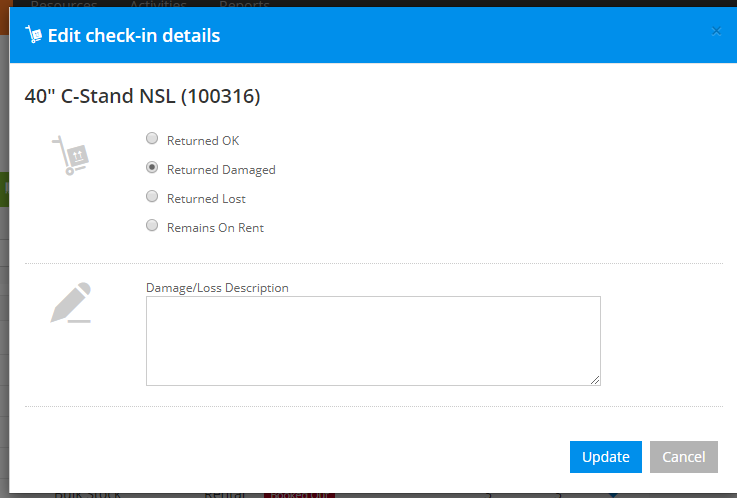

b) For Serialized Items, Click the triangle menu and select check-in.

You get the following pop-up. Select the reason, write a note. The item will be put in quarantine. If damaged, put a damage tag on the item.

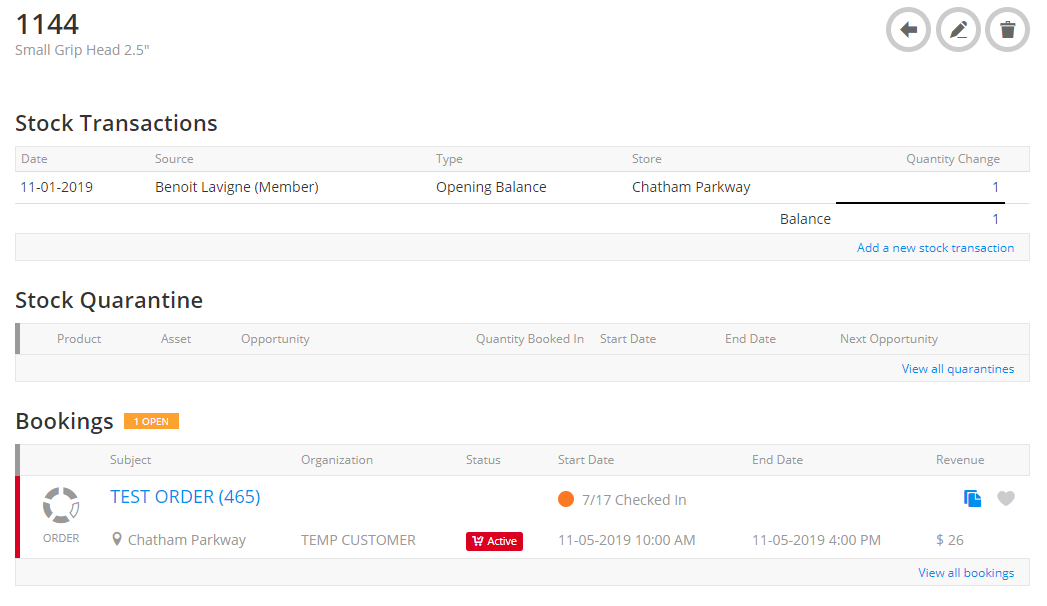

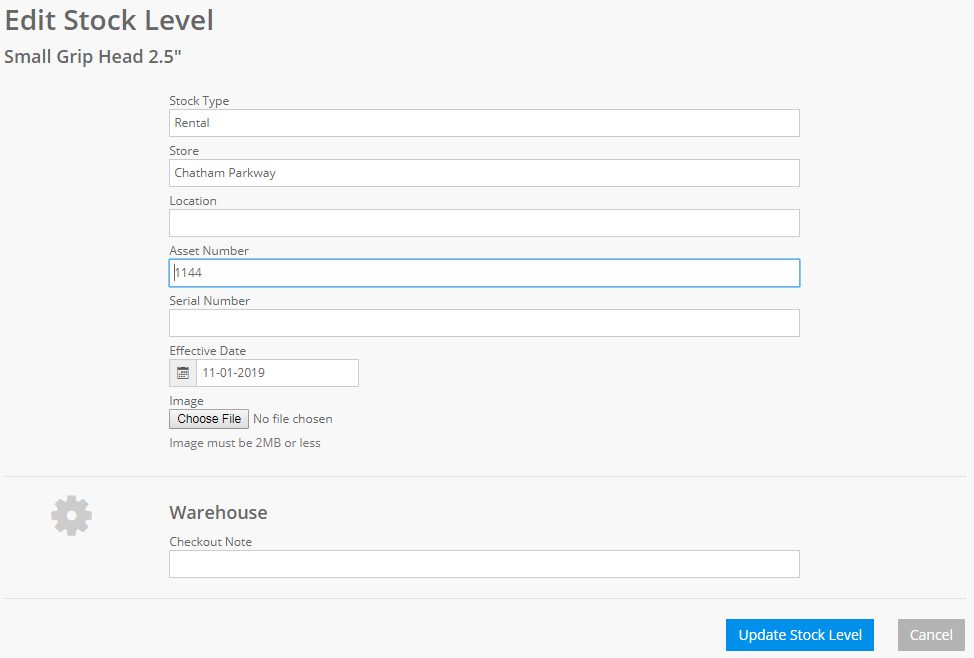

4. For Serialized Items, If something should be noted permanently on the item (i.e. burn marks on rag):

- select the item asset number

- edit the item and put the note in the Warehouse Checkout note.

When the item goes out on the next checkout, we'll know it's a pre-existing condition.

5. When all the items have been processed, anything that has not been checked in should be marked as missing (see Step 3) and the client informed.

6. In the Functions Tab, once everything is processed, select "Finalize Return".

This will close out the opportunity and indicate that the warehouse has nothing left to do with this job.

All broken or Missing equipment are dealt with in the Quarantine module.

Reference

- CurrentRMS Check-in products article